![What-is-fiberglass]()

Fiberglass is a critical material in industries such as construction, automotive, electronics, and renewable energy. It offers high tensile strength, thermal resistance, and electrical insulation, making it ideal for protective garments, composite structures, and insulation layers. However, during handling, tiny fiberglass fibers can adhere to work clothes, causing skin irritation, discomfort, and contamination. Proper cleaning and protective strategies are essential for industrial safety.

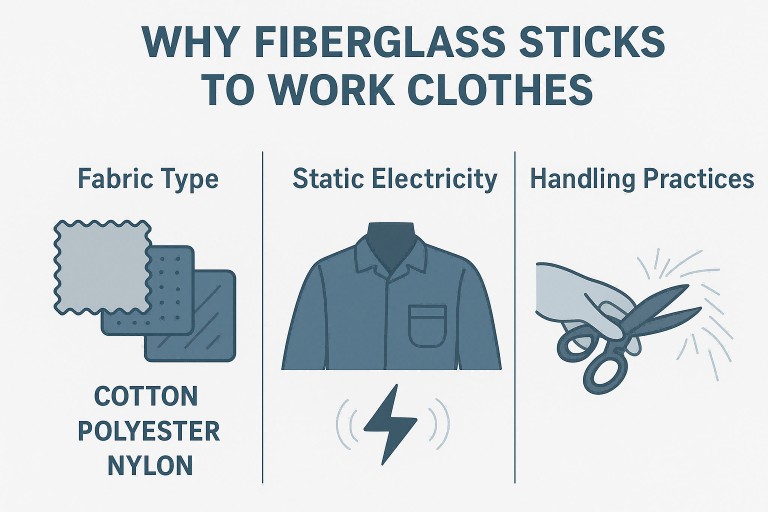

Why Fiberglass Sticks to Work Clothes

Fiberglass fibers are extremely fine—often smaller than human hair—and lightweight, which allows them to penetrate fabric gaps easily. This makes contamination a common issue in industrial settings.

Key Factors Influencing Fiber Adhesion

Fabric Type:

Work clothes made from synthetic materials like polyester or nylon tend to attract more fibers due to static. Natural fibers like cotton are slightly less prone but can still retain fibers with prolonged exposure.

Static Electricity:

Static charges generated during handling can cause fibers to cling to clothes. Anti-static uniforms and workstations help reduce fiber adherence.

Handling Practices:

Improper handling, such as cutting, sanding, or rolling fiberglass sheets (roll of fiberglass cloth) without protection, increases the likelihood of fiber transfer.

![Fiberglass Sticks to Work Clothes]()

Industrial Implications

Fiberglass fibers on work clothes are more than a comfort issue—they pose safety risks. Exposure can cause skin irritation or respiratory issues. Contaminated clothing can also transfer fibers to other areas of a facility, affecting product quality and hygiene.

Industrial Methods for Removing Fiberglass from Work Clothes

Proper cleaning techniques protect workers and extend the lifespan of industrial uniforms.

1.Shake and Brush Off Fibers

Shake clothes outdoors or in a controlled environment to remove loose fibers.

Use a soft brush, rubber gloves, or lint roller to gently dislodge fibers from the surface, preventing deeper embedding.

For high-density woven fiberglass cloth uniforms, gentle brushing removes most surface fibers efficiently.

2.Cold Water Rinse

Rinse workwear in cold water before a full wash to prevent fibers from adhering further.

For heavier contamination, multiple rinse cycles or soaking in water with mild detergent is recommended.

Adding anti-static agents can further reduce fiber attachment.

3.Industrial Laundry Practices

Wash fiberglass-contaminated clothing separately to avoid cross-contamination.

Use mild detergents compatible with high-performance fabrics like electronic grade fiberglass cloth.

Avoid high-heat drying; air-drying preserves fabric integrity and prevents fibers from embedding permanently.

4.Specialized Cleaning Equipment

Industrial facilities may use ultrasonic cleaning or filtration washers for heavily contaminated garments.

These methods are particularly effective for uniforms made with roll of fiberglass cloth, ensuring fibers are removed without damaging the material.

![Removing Fiberglass from Work Clothes]()

Protective Measures for Employees

Prevention is better than cleaning. Proper protective measures reduce fiber exposure and contamination.

![Use uniforms made from woven fiberglass cloth]()

Wear Specialized Protective Clothing

Use uniforms made from woven fiberglass cloth or disposable protective suits.

High-density or pre-treated fiberglass garments reduce fiber adherence.

Long sleeves, gloves, and safety goggles protect skin and eyes from irritation.

Designated Changing and Laundry Areas

Separate zones for changing, washing, and storing contaminated clothing prevent fibers from spreading.

Industrial laundry facilities with filtration systems ensure thorough cleaning.

B2B Consideration

For companies managing multiple industrial sites, investing in roll of fiberglass cloth uniforms or pre-fabricated protective wear ensures uniform quality and reduces fiber-related incidents.

Bulk sourcing of woven fiberglass cloth protective clothing ensures consistent standards and compliance.

Benefits of Electronic Grade Fiberglass Cloth

Electronic grade fiberglass cloth offers unique properties suitable for high-precision industries:

High purity and low alkali content reduce contamination risks during electronics assembly.

Smooth surface and precise weave make it ideal for PCB workstations, transformers, or insulation layers.

Durable yet lightweight, maintaining dimensional stability even after repeated handling and cleaning.

Industrial Applications

Electronics Manufacturing:

Prevents fiber shedding on sensitive components.

Aerospace and Defense:

Insulation layers and protective covers for high-temperature applications.

Renewable Energy:

Lightweight protective sheets for turbines and wind equipment.

B2B Advantage

Supplying electronic grade fiberglass cloth for uniforms or protective covers improves safety standards and reduces maintenance costs.

Ensures compliance with international quality standards for industrial operations.

Conclusion

Managing fiberglass on work clothes is essential for worker safety, garment longevity, and operational efficiency. Using woven fiberglass cloth, roll of fiberglass cloth, and electronic grade fiberglass cloth for uniforms and protective wear significantly reduces fiber contamination and safety risks.

B2B Recommendation: Invest in high-quality fiberglass-resistant workwear and partner with professional industrial laundry services. This ensures a safer, cleaner, and more efficient workplace while lowering long-term operational costs.

English

العربية

Français

Русский

Español

Português

Deutsch

italiano

日本語

한국어

Nederlands

Tiếng Việt

ไทย

Polski

Türkçe

Bahasa Melayu

Filipino

Bahasa Indonesia

magyar

Română

Čeština

қазақ

Српски

हिन्दी

فارسی

Slovenčina

Slovenščina

Norsk

Svenska

українська

Ελληνικά

Suomi

Հայերեն

עברית

Dansk

اردو

বাংলা

Hrvatski

Afrikaans

Gaeilge

Eesti keel

Māori

नेपाली

Oʻzbekcha

latviešu

Azərbaycan dili

Беларуская мова

Български

ქართული

Kurdî

Кыргызча