Choosing the right carbon fiber fabric is essential if you want to achieve the best performance, appearance, and production efficiency in your composite projects. Each application has its own structural and aesthetic requirements, so the fabric you choose directly affects the strength, weight, and durability of your final product.

At Jlon, we understand that every detail matters. That’s why we provide a full range of carbon fiber fabrics designed to meet your exact needs — whether you’re optimizing for stiffness, flexibility, surface finish, or process efficiency. Our materials help you achieve superior results while keeping your production precise and consistent.

![Carbon fiber fabric]()

Understanding the Differences

Different types of carbon fiber fabrics vary in fiber orientation, weave pattern, resin compatibility, and mechanical properties.

By understanding these distinctions, you can select the most suitable material for your project’s performance and appearance goals.

Below, Jlon presents a detailed guide to the main types of carbon fiber fabrics and practical tips on how to choose the right one for your specific application.

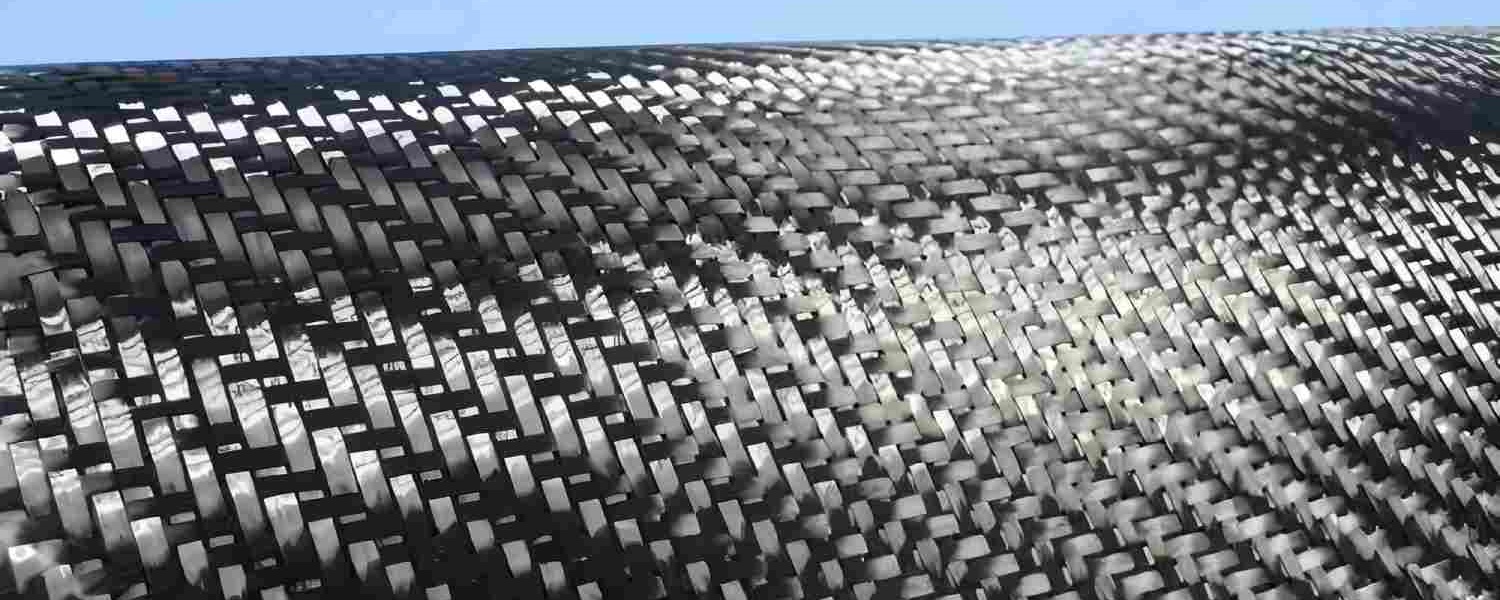

1. Woven Carbon Fiber Fabric

![Woven Carbon Fiber Fabric]()

Overview:

Woven carbon fiber fabrics consist of interlaced warp and weft fibers, providing balanced strength in two directions and excellent dimensional stability.

Common weaves include:

Plain weave: tight, stable structure with a fine pattern

Twill weave: flexible, smooth surface with a distinctive diagonal appearance

Satin weave: soft and drapable, suitable for complex shapes

Technical Data:

Fiber Type: T300 / T700 / T800

Areal Weight: 200–300 gsm

Thickness: 0.25–0.35 mm

Width: 1000–1250 mm

Resin Compatibility: Epoxy, Vinyl Ester, Polyester

Mechanical Properties:

Tensile Strength: 3500–4900 MPa

Elastic Modulus: 230–245 GPa

Density: 1.76 g/cm³

Processing Method:

Suitable for hand lay-up, vacuum infusion (VARTM), and RTM

Works well on flat or moderately curved molds

Recommended Applications:

Automotive body parts, sports equipment, drone shells, molds, and decorative panels.

Selection Tip:

Use plain weave for stability and twill weave when both flexibility and surface aesthetics are important.

2. UD (Unidirectional) Carbon Fiber Fabric

![UD Carbon Fiber Fabric]()

Overview:

UD fabrics align all fibers in one direction, maximizing strength and stiffness along that axis. They are ideal for reinforcing parts subjected to directional loads.

Technical Data:

Areal Weight: 150–300 gsm

Thickness: 0.2–0.35 mm

Fiber Alignment Accuracy: High

Mechanical Properties:

Tensile Strength (0°): 4000–4900 MPa

Modulus: 230–240 GPa

Elongation: 1.5–2.0%

Processing Method:

Suitable for prepreg, pultrusion, and vacuum infusion

Often layered in alternating 0°/90° orientation for structural balance

Recommended Applications:

Aerospace structures, wind turbine blades, UAV arms, and structural reinforcement panels.

Selection Tip:

Choose UD fabric when load direction is clearly defined and maximum directional stiffness is required.

3. Carbon Fiber Kevlar Cloth

![Carbon Fiber Kevlar Cloth]()

Overview:

Hybrid fabric combining carbon fiber (for stiffness) and Kevlar aramid fiber (for toughness), offering a balance between strength, impact resistance, and durability.

Typical Ratio: 50% Carbon + 50% Kevlar

Common Colors: Black/yellow, black/red, black/blue

Technical Data:

Areal Weight: 200–280 gsm

Thickness: 0.3–0.4 mm

Density: 1.5–1.6 g/cm³

Mechanical Properties:

Up to 40% higher impact resistance compared to pure carbon fabric

Excellent tear and abrasion resistance

Processing Method:

Compatible with hand lay-up and vacuum infusion

Kevlar is non-conductive, suitable for insulation applications

Recommended Applications:

Motorcycle fairings, racing shells, protective gear, and abrasion-resistant panels.

Selection Tip:

Select Carbon Kevlar cloth when components require both lightweight strength and high impact resistance.

4. Carbon Spread Tow Fabric

![Carbon Spread Tow Fabric]()

Overview:

Spread tow fabrics use flattened carbon fiber tows to create a lightweight, smooth weave with minimal crimp. This improves mechanical performance and surface finish.

Technical Data:

Areal Weight: 150–250 gsm

Thickness: ~0.2 mm

Width: 1000–1500 mm

Mechanical Properties:

10–15% higher tensile strength than standard woven fabrics

Excellent surface flatness and low resin consumption

Processing Method:

Suitable for vacuum infusion and autoclave curing

Produces high-gloss, aesthetic surface finishes

Recommended Applications:

High-end automotive panels, drones, electronics housings, and sports products.

Selection Tip:

Ideal for projects that demand both high performance and premium appearance.

5. Color Carbon Fiber Fabric

![Color Carbon Fiber Fabric]()

Overview:

Color carbon fiber fabric incorporates colored fibers or coatings into carbon fiber fabrics, combining mechanical strength with decorative appeal.

Coloring Methods:

Colored fiber blending

Metallic coating

Transparent surface films

Common Colors: Red, blue, silver, gold, green, and more

Performance Features:

Excellent UV resistance and color stability

Durable surface finish without fading

Recommended Applications:

Decorative panels, consumer electronics, automotive interiors, and design products.

Selection Tip:

Best choice for aesthetic or branding-oriented applications where visual impact matters.

6. Carbon Fiber Fabric Prepreg

![Carbon Fiber Fabric Prepreg]()

Overview:

Prepreg carbon fiber fabric is pre-impregnated with a controlled amount of resin, offering superior strength, precision, and consistency.

Technical Data:

Resin System: Epoxy / BMI / Cyanate Ester

Resin Content: 35–40%

Glass Transition Temperature (Tg): 120–180°C

Curing Conditions: 120°C / 2h or 135°C / 1h

Processing Method:

Must be stored in low temperature (freezer)

Requires autoclave, compression molding, or oven curing

Excellent fiber-resin ratio control

Recommended Applications:

Aerospace parts, racing car chassis, bicycle frames, and high-performance UAVs.

Selection Tip:

Choose prepreg for precision-engineered, high-strength components where performance consistency is critical.

7. Multiaxial Carbon Fiber Fabric

![Multiaxial Carbon Fiber Fabric]()

Overview:

Multiaxial fabrics are non-crimp laminates with fibers oriented in multiple directions (0°, 90°, ±45°).

They provide multi-directional reinforcement and superior fatigue resistance.

Technical Data:

Configuration: Biaxial / Triaxial / Quadraxial

Areal Weight: 300–600 gsm

Thickness: 0.4–0.8 mm

Mechanical Properties:

Balanced strength in multiple directions

Excellent fatigue and delamination resistance

Processing Method:

Ideal for large-scale vacuum infusion and RTM processes

Recommended Applications:

Wind turbine blades, yacht hulls, bridges, and heavy structural components.

Selection Tip:

Select multiaxial fabric for large structures requiring balanced load distribution.

Comparison Table

Fabric Type | Structure | Key Strengths | Recommended Applications |

Woven Fabric | Bidirectional weave | Balanced strength | Automotive, sports goods |

UD Fabric | Unidirectional | Maximum stiffness in one direction | Aerospace, reinforcement |

Carbon Kevlar | Hybrid | Impact and abrasion resistance | Protective components |

Spread Tow | Flat tow weave | Lightweight, smooth finish | Automotive panels |

Color Fabric | Colored fiber blend | Decorative and strong | Design and consumer products |

Prepreg | Resin pre-impregnated | High precision and consistency | Aerospace, racing |

Multiaxial | Multi-directional layers | All-directional strength | Marine, structural parts |

Conclusion

Selecting the right carbon fiber fabric means understanding how each type supports your project’s goals — whether you prioritize stiffness, flexibility, impact resistance, or visual appeal.

With Jlon, you don’t have to decide alone. Our experts help you evaluate material options, processing methods, and mechanical requirements, ensuring your composite solutions deliver top performance and long-term reliability.

From aerospace to automotive, Jlon is your trusted partner in advanced carbon fiber technology.

![the Differences of carbon fiber fabrics]()

English

العربية

Français

Русский

Español

Português

Deutsch

italiano

日本語

한국어

Nederlands

Tiếng Việt

ไทย

Polski

Türkçe

Bahasa Melayu

Filipino

Bahasa Indonesia

magyar

Română

Čeština

қазақ

Српски

हिन्दी

فارسی

Slovenčina

Slovenščina

Norsk

Svenska

українська

Ελληνικά

Suomi

Հայերեն

עברית

Dansk

اردو

বাংলা

Hrvatski

Afrikaans

Gaeilge

Eesti keel

Māori

नेपाली

Oʻzbekcha

latviešu

Azərbaycan dili

Беларуская мова

Български

ქართული

Kurdî

Кыргызча