Technical Deta sheet of Fiberglass Cloth

![]() TDS-2116 fiberglass cloth Impregnated.pdf

TDS-2116 fiberglass cloth Impregnated.pdf

![]() TDS-7628 fiberglass cloth Impregnated.pdf

TDS-7628 fiberglass cloth Impregnated.pdf

![]() TDS-7642 fiberglass cloth Impregnated.pdf

TDS-7642 fiberglass cloth Impregnated.pdf

![]() TDS-7637 fiberglass cloth Impregnated.pdf

TDS-7637 fiberglass cloth Impregnated.pdf

![]() TDS-1080 fiberglass cloth Impregnated.pdf

TDS-1080 fiberglass cloth Impregnated.pdf

Introduction of Fiberglass Cloth

Fiberglass Cloth for PCB are adopted electric grade fiberglass and processed in plain textile by air jet machines and with surface chemical treatment. Electronic fiberglass fabric is plain weaved on air-jet looms by intersecting warp and weft,the fabric surface is treated after 1st and 2nd de-sizing for designed electrical insulation properties,physical & chemical proerties and processing performances of Copper-clad laminates.

Whether you need to reinforce structures, create insulation barriers, or protect against heat and fire, this fiberglass fabric is a reliable choice. Its versatility and superior performance make it suitable for cross-border e-commerce platforms, catering to customers worldwide.

Video of Fiberglass Cloth

Features of Fiberglass Cloth

1.High strength,heat resistance,fire-retardant and insulation

2.High pressure strand spreading and easy for resin impregnation

3.Treated with silance coupling agent and excellent compatibility with resins

Specification of Fiberglass Cloth

Style | Fabric Count Warp*Weft (Per cm) | Yarn Warp*Weft (SI) | Thickness (mm) | Weight (g/m2) | Weave |

1080 | 23.6*18.5 | 5 11 1*0 5 11 1*0 | 0.053 | 46.8 | Plain |

1280 | 23.6*23.6 | 5 11 1*0 5 11 1*0 | 0.056 | 52.9 | Plain |

1500 | 19.3*16.5 | 7 45 1*0 7 45 1*0 | 0.149 | 164.1 | Plain |

1501 | 18.1*17.7 | 7 45 1*0 7 45 1*0 | 0.140 | 1654.0 | Plain |

1504 | 23.6*19.7 | 6 33 1*0 6 33 1*0 | 0.125 | 148.0 | Plain |

1506 | 18.2*18.2 | 7 45 1*0 7 45 1*0 | 0.140 | 165.0 | Plain |

1651 | 20.0*10.8 | 9 33 1 *0 9 7 41*0 | 0.135 | 146.2 | Plain |

1652 | 20.5*20.5 | 9 34 1*0 9 34 1*0 | 0.114 | 13.83 | Plain |

1674 | 15.7*12.6 | 9 34 1*0 9 34 1*0 | 0.097 | 96.6 | Plain |

1675 | 15.7*12.6 | 6 33 1*0 6 33 1*0 | 0.101 | 96.3 | Plain |

1678 | 15.7*15.7 | 9 34 1*0 9 34 1*0 | 0.091 | 103.5 | Plain |

2113 | 23.6*22.0 | 7 22 1*0 5 11 1*0 | 0.079 | 78.0 | Plain |

2114 | 22.0*158.9 | 7 22 1*0 7 22 1*0 | 0.084 | 90.9 | Plain |

2116 | 23.6*22.8 | 7 22 1*0 7 22 1*0 | 0.094 | 103.8 | Plain |

2117 | 26.0*21.7 | 7 22 1*0 7 22 1*0 | 0.095 | 108 | Plain |

2125 | 15.7*15.4 | 7 22 1*0 9 34 1*0 | 0.091 | 87.5 | Plain |

2157 | 23.6*13.8 | 7 22 1*0 9 68 1*0 | 0.130 | 148.0 | Plain |

2165 | 23.6*20.5 | 7 22 1*0 9 34 1*0 | 0.101 | 122.4 | Plain |

2166 | 23.6*15.0 | 7 22 1*0 9 68 1*0 | 0.140 | 155.0 | Plain |

2313 | 24.0*24.8 | 616.5 1*0 5 11 1*0 | 0.084 | 81.4 | Plain |

3070 | 27.6*27.6 | 616.5 1*0 616.5 1*0 | 0.078 | 93.6 | Plain |

3313 | 23.6*24.4 | 616.5 1*0 616.5 1*0 | 0.084 | 81.4 | Plain |

7628 | 17.3*12.2 | 9 68 1*0 9 68 1*0 | 0.173 | 203.4 | Plain |

7629 | 17.9*13.4 | 9 68 1*0 9 68 1*0 | 0.18 | 210.0 | Plain |

7635 | 17.3*11.4 | 9 68 1*0 9 102 1*0 | 0.201 | 232.3 | Plain |

7642 | 17.5*7.9 | 9 68 1*0 9 136 1*0 | 0.254 | 227.8 | Plain |

7637 | 17.45*8.8 | 9 68 1*0 9 136 1*0 | 0.240 | 255.0 | Plain |

7638 | 17.4*10.0 | 9 68 1*0 9 136 1*0 | 0.250 | 260.0 | Plain |

336 | 18.89*12.59 | 9 136 1*0 9 136 1*0 | 0.360 | 432.0 | Plain |

985 | 47.2*25.4 | 5 11 1*0 5 11 1*0 | 0.130 | 139.0 | Plain |

Details:

1) Standard fabric/Impregnated fabric (can only be made on air jet looms)

Warp and weft: 9um G75, 68tex starch yarn

Application: Copper Clad, Insulation Board

Process: Warping and spinning, weaving, desizing, smoldering, surface treatment (adding coupling agent to increase strength), packaging

2) Imitation cloth

Warp:H series yarn,11um H75 68tex low wax yarn

Weft: 9um G75, 68tex starch yarn (same as standard fabric/Impregnated fabric)

Application: Copper Clad, Insulation Board

Process: Warping and spinning, weaving, desizing, smoldering, surface treatment (adding coupling agent to increase strength), packaging

3) Electrical cloth

140g

160g

190g

200g

Warp and weft: 9um G75, 68tex starch yarn

Application: Melamine board - electrical switch

4) Industrial fabric

3732

17 * 13 warp and weft density

warp and weft G37 yarn, 9um, 136tex

420G

regular satin pattern, customizable plain/ twill pattern

Application:

Apply silicone to make silicone products - ventilation pipes, soft links

Fire blanket

5) Loomstate fabric

140g cloth

12 * 9 warp and weft density

warp and weft: 68tex yarn, 13um yarn

260g cloth

12 * 8 warp and weft density

warp and weft: 134tex yarn, 13um

3732 cloth, 420g

Warp and weft density 20 * 10

warp and weft: 140tex yarn, 13um/11um

3784 cloth, 600-850g

According to the different weft density and weight, density of warp and weft is 18 * (7-10)

Warp: 232tex yarn(136tex * 2)

Weft: 330tex or 350tex(Direct yarn)

Can undergo one desizing treatment

Production process of Fiberglass Cloth

Warping&Sizing, Parallel axis, Denting, Weaving, Pre-desizing, Second desizing, Surface treatment, Inspection![Fiberglass Cloth生产流程]()

Production Line of Fiberglass Cloth

We have professional production team and technical team to satisfy clients's different fabric requirement. We have 150 sets of weaving machines to meet clients's delivery needs.

![Fiberglass Cloth1]()

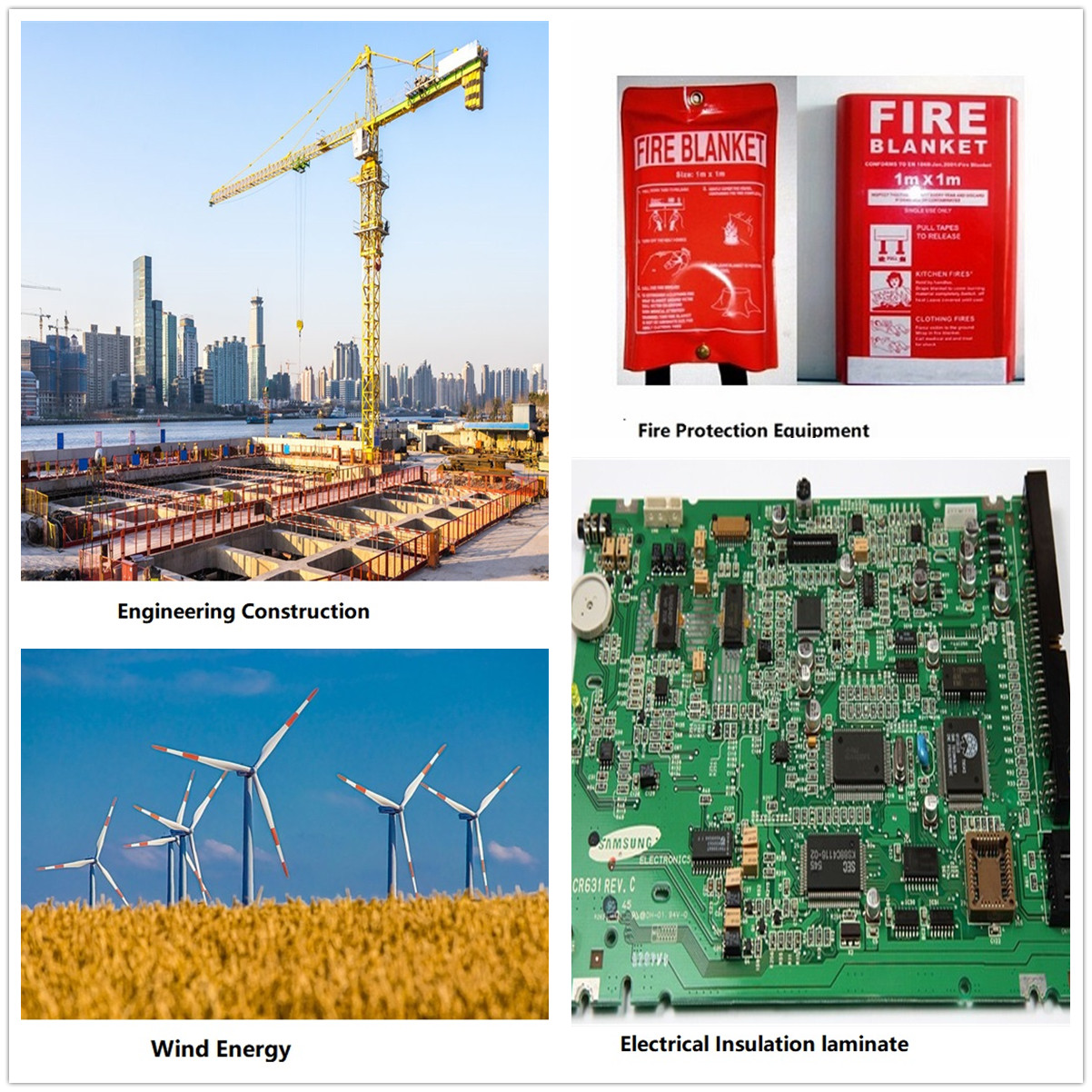

Application of Fiberglass Cloth

It is widely used in the electric insulation as it prevents the system from high impact by equally spreading the stress in different direction, such as PCB(Printed Circuit Board), CCL(Copper Clad Laminate.

It is also used in chemical industry, pipeline ductile conjunction, machinery, sound absorption, anti-fire agent and so on.

![Fiberglass Cloth]()

Transport and Shipping of Fiberglass Cloth

Fiberglass cloth is one of our common product, we have different kinds of stock to meet client's urgent small order quantity.

Also, our production time for Fiberglass cloth is only 7-10days, so if you have bulk order of urgent delivery time, we can satisfy you.

![Fiberglass Cloth]()

Packaging and Storage of Fiberglass Cloth

Roll packaging: PE plastic film

Pallet packaging: Pallets should NOTbe stacked in more than 2 layers.

This product should be stored in a dry, ventilated and rainproof place, with temperatures from 5℃to 35℃ and humidity between 35% and 65%. It is recommended to be kept in intact package when not used to avoid damp.

Company profile

Changzhou JLON Composite Co., Ltd.

A company who believes a satisfied customer is the best business accomplishment.

Changzhou JLON Composite Co. provides a wide range of reinforcements tailored to many applications such as construction, marine, pultruded profiles, transportation, wind energy, sports, etc. We’re one stop source for FRP raw materials.

In recent years we’ve entered new business axial fan and PVB/SGP film. Now there’re mainly two business sectors in our company:

A. Composite reinforcement materials and building materials:

Fiberglass products such as roving, chopped strand mat, woven roving, stitch mat, multiaxials, infusion mat, nonwovens for roofing, flooring, ceiling and walls of buildings

High performance fiber such as carbon fiber, aramid fiber, basalt fiber, high silica fiberglass, quartz

Core materials such as PVC/PET foam, PP honeycomb

Chemicals such as UP resin, vinyl ester resin, epoxy resin, SMC/BMC, MDI

Auxiliary materials such as infusion consumables, FRP tools

B. Axial fan:

We provide PAG and aluminum axial fan for HVAC, engineering equipment...We have different blades, hubs to satisfy customers’ specific needs.

FAQs of Fiberglass Cloth

Q1.Can your company customize products?

A: Yes, We usually discuss with customers and help them find solutions.

Q2.How can I get a sample from you to check quality?

A: Usually a sample will be prepared within one week after specification agreed.

Q3.What about your delivery time? Can we receive our goods on time?

A: Usually around 2-3 weeks after order confirmed. Exact delivery time depends on order quantity and Off-season/ busy season.

Q4.What is the Guarantee to buy your products? How to resolve qualitycomplaints?

A: Offer TDS of each lot of production for confirmation before delivery.Once you have any quality problem, you can provide samples /pictures test data With our quality tracking system, we will give you feedback in short time. If the quality problem confirmed,we will send you replacement or make refund as you like.

Q5.What are your terms of payment?

A: Usually we do EXW, FOB, CIF and DDU

English

العربية

Français

Русский

Español

Português

Deutsch

italiano

日本語

한국어

Nederlands

Tiếng Việt

ไทย

Polski

Türkçe

Bahasa Melayu

Filipino

Bahasa Indonesia

magyar

Română

Čeština

қазақ

Српски

हिन्दी

فارسی

Slovenčina

Slovenščina

Norsk

Svenska

українська

Ελληνικά

Suomi

Հայերեն

עברית

Dansk

اردو

বাংলা

Hrvatski

Afrikaans

Gaeilge

Eesti keel

Māori

नेपाली

Oʻzbekcha

latviešu

Azərbaycan dili

Беларуская мова

Български

ქართული

Kurdî

Кыргызча