If you work with composite materials, coatings, or adhesives, you’ve likely come across Polyester Resins. These versatile polymers are mainly divided into Saturated Polyester Resin (SPR) and Unsaturated Polyester Resin (UPR).

Although they share a similar chemical foundation, they differ significantly in structure, curing mechanism, and application performance.

At JLON, we focus on producing high-performance Unsaturated Polyester Resins tailored for fiberglass reinforcement, marine structures, and industrial composites.

By understanding the difference between these two types, you’ll be able to choose the right resin system for your specific project.

![polyester resin]()

Chemical Structure and Composition

![between saturated polyester resin]()

Saturated Polyester Resin (SPR)

Saturated polyester resin is created by reacting polyacids (such as adipic acid or phthalic anhydride) with polyols (like ethylene glycol or neopentyl glycol).

Because its molecular chain is fully saturated and contains no carbon–carbon double bonds (C=C), it cannot crosslink during curing.

This makes SPR a linear, thermoplastic material—ideal when flexibility and solvent compatibility are key.

![unsaturated polyester resin]()

Unsaturated Polyester Resin (UPR)

Unsaturated polyester resin, on the other hand, contains reactive double bonds (C=C) introduced by unsaturated acids such as maleic anhydride or fumaric acid.

These double bonds allow the resin to crosslink with reactive monomers (commonly styrene) and form a three-dimensional thermoset structure after curing.

This is why UPR offers superior mechanical strength, heat resistance, and dimensional stability, making it your best choice for fiberglass composite applications.

Manufacturing Process

1. How Saturated Polyester Resin Is Made

You can produce saturated polyester resin through polycondensation under controlled temperature and vacuum, resulting in a viscous polymer.

This resin is usually dissolved in organic solvents to make coatings, films, or adhesives—no reactive monomer is required for curing.

2. How Unsaturated Polyester Resin Is Made

To make unsaturated polyester resin, you include unsaturated acids during the reaction process.

The prepolymer is then blended with a reactive monomer (like styrene) to adjust viscosity and enable crosslinking.

When you add a catalyst such as MEKP (methyl ethyl ketone peroxide), it initiates free-radical polymerization, turning the liquid resin into a solid, durable thermoset.

At JLON, you can rely on our advanced production controls and strict temperature management to ensure consistent polymerization, acid values, and mechanical stability in every batch.

Key Property Differences

Property | Saturated Polyester Resin (SPR) | Unsaturated Polyester Resin (UPR) |

Molecular Structure | Fully saturated (no C=C bonds) | Contains C=C double bonds |

Curing Behavior | Thermoplastic, non-crosslinking | Thermoset, crosslinking with styrene |

Solubility | Solvent-based | Diluted with reactive monomers |

Flexibility | High | Moderate to high (formulation dependent) |

Thermal Resistance | Moderate | High (up to 180–200°C) |

Chemical Resistance | Excellent for coatings | Excellent after curing |

Processing | Solvent coating or extrusion | Hand lay-up, SMC/BMC, RTM, pultrusion |

Cost Efficiency | Moderate | Cost-effective for composites |

Major Applications | Paints, coatings, adhesives, films | FRP, marine, construction, automotive |

Industrial Applications

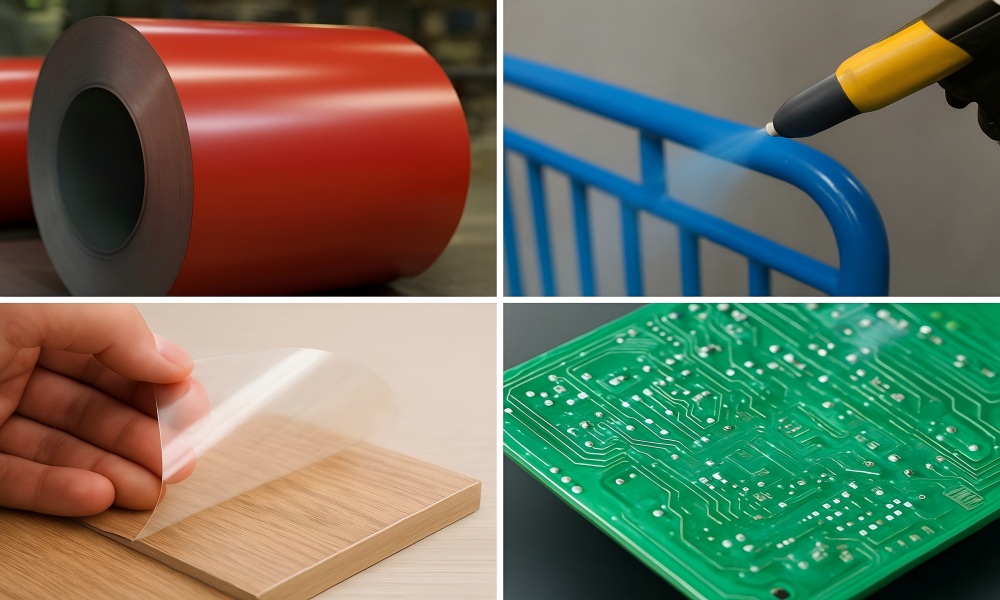

Applications of Saturated Polyester Resin (SPR)

Saturated Polyester Resin (SPR) is a thermoplastic resin, primarily used for coatings, adhesives, and films. Its fully saturated molecular structure makes it flexible and solvent-compatible, which is ideal for protective and decorative applications.

Key Applications:

Metal and Coil Coatings for Corrosion Protection

SPR forms a uniform, flexible coating that adheres well to metal surfaces.

Provides excellent resistance to moisture, corrosion, and mild chemicals.

Example: Coating of steel coils used in building facades or appliance panels.

Powder Coatings with Superior Outdoor Durability

Ideal for UV-resistant powder coatings due to good thermal stability.

Maintains color, gloss, and surface integrity under prolonged outdoor exposure.

Example: Outdoor furniture, metal gates, and architectural panels.

Industrial Paints and Laminating Films

Offers smooth film formation, excellent adhesion, and flexibility.

Resistant to cracking or peeling under mechanical stress.

Example: Laminates for furniture, flooring, or protective industrial surfaces.

Adhesives and Electrical Insulation Coatings

Solvent-based SPR adhesives provide strong bonding on metals, plastics, and composites.

Can be used in electrical insulation coatings due to flexibility and chemical resistance.

Example: Coating wires, printed circuit boards (PCBs), and insulating components.

![APPLICATION OF SPR]()

Applications of Unsaturated Polyester Resin (UPR)

Unsaturated Polyester Resin (UPR) is the most widely used thermosetting resin in the composite industry. Its reactive C=C bonds allow crosslinking, resulting in strong, durable, and dimensionally stable materials.

Key Applications:

FRP (Fiberglass Reinforced Plastic): Panels, Tanks, and Pipes

UPR combined with fiberglass produces lightweight, corrosion-resistant FRP products.

Excellent dimensional stability and impact resistance under long-term mechanical load.

Example: Chemical storage tanks, water treatment piping, industrial panels.

Marine Applications: Boat Hulls, Decks, and Storage Tanks

UPR-based FRP structures are highly resistant to water, salt, and UV exposure.

Lightweight yet strong, ensuring fuel efficiency and structural integrity.

Example: Small to medium-sized boats, floating docks, marine storage tanks.

Construction: Wall Panels, Roofing, and Profiles

High mechanical strength and thermal resistance make UPR ideal for structural panels.

Compatible with reinforcement materials for load-bearing applications.

Example: Prefabricated wall panels, roof sheets, architectural profiles.

Automotive: Bumpers, Body Kits, and SMC/BMC Components

UPR enables molding of complex shapes with high surface quality.

Offers good impact resistance and durability in automotive parts.

Example: Exterior bumpers, SMC body panels, interior decorative trims.

Electrical: Insulators, Switch Housings, Junction Boxes

High dielectric strength and dimensional stability ensure safety and performance.

Resistant to heat, moisture, and chemical exposure.

Example: Switchgear housings, insulators for transformers, junction boxes.

Decorative Materials: Artificial Marble and Sanitary Ware

UPR provides smooth surface finish, excellent polishability, and color retention.

Chemically resistant and easy to mold into complex shapes.

Example: Countertops, sinks, bathtubs, and decorative panels.

![APPLICATION OF UPR]()

Why Choose JLON’s Unsaturated Polyester Resin

JLON Unsaturated Polyester Resin (UPR) offers multiple advantages in mechanical performance, processability, and durability, making it ideal for composites, marine structures, construction, and industrial applications.

1. High Mechanical Strength and Dimensional Stability

Forms a three-dimensional crosslinked network after curing, providing excellent tensile, flexural, and impact strength.

Superior dimensional stability ensures components maintain shape and accuracy under high temperature and humid conditions.

Applications: FRP tanks, boat panels, automotive SMC/BMC structural parts withstand long-term mechanical stress without deformation.

2. Strong Bonding with Fiberglass, Fillers, and Core Materials

Surface treatment and silane coupling agents enhance adhesion to fiberglass, mineral fillers, and foam cores.

Excellent wet-out ensures uniform resin penetration and minimizes air bubbles or voids.

Applications: Multi-layer FRP laminates, boat decks, and composite sandwich panels achieve maximum structural integrity and durability.

3. Excellent Heat and Chemical Resistance (Up to 180°C)

High-purity UPR can withstand elevated temperatures, suitable for industrial equipment and high-temperature environments.

Resistant to acids, alkalis, and many organic solvents, ensuring long-term chemical durability.

Applications: Chemical storage tanks, piping systems, and industrial corrosion-resistant laminates remain stable in harsh environments.

4. Optimized Viscosity for Easier Processing

Viscosity is precisely controlled to meet the requirements of hand lay-up, spray-up, RTM, and compression molding processes.

Optimized viscosity ensures easier resin application, full fiberglass wetting, and reduces air entrapment and material waste.

Applications: Hand-laminated FRP, boat hulls, and automotive BMC parts improve production efficiency and product consistency.

5. Consistent Curing Performance for Uniform Product Quality

Batch-to-batch curing speed and gel time are consistent, preventing incomplete curing or performance variations.

Ensures final components meet mechanical, thermal, and chemical performance standards reliably.

Applications: Industrial tanks, marine structures, and construction panels achieve predictable, long-lasting results for every product.

![Choose JLON’s Unsaturated Polyester Resin]()

Our Quality Commitment

Every batch of JLON UPR is manufactured and tested according to ISO and ASTM standards.

We test viscosity, gel time, acid value, and mechanical properties—so you can count on stable and repeatable results.

Available Resin Grades

General-purpose UPR: for FRP panels, pipes, and tanks

Marine-grade UPR: improved hydrolysis and mechanical strength

Fire-retardant UPR: halogen-free and low smoke emission

High-strength UPR: ideal for SMC/BMC and structural applications

Conclusion

In short, the key difference between saturated and unsaturated polyester resin lies in their chemical structure and curing behavior:

Saturated Polyester Resin stays thermoplastic and is mostly used for coatings and adhesives.

Unsatrated Polyester Resin can crosslink and cure into a strong thermoset, making it ideal for fiberglass composites.

If you’re looking for high-performance, reliable Unsaturated Polyester Resin, JLON offers a full range of formulations for marine, automotive, construction, and industrial applications—helping you achieve the durability and performance your products need.

English

العربية

Français

Русский

Español

Português

Deutsch

italiano

日本語

한국어

Nederlands

Tiếng Việt

ไทย

Polski

Türkçe

Bahasa Melayu

Filipino

Bahasa Indonesia

magyar

Română

Čeština

қазақ

Српски

हिन्दी

فارسی

Slovenčina

Slovenščina

Norsk

Svenska

українська

Ελληνικά

Suomi

Հայերեն

עברית

Dansk

اردو

বাংলা

Hrvatski

Afrikaans

Gaeilge

Eesti keel

Māori

नेपाली

Oʻzbekcha

latviešu

Azərbaycan dili

Беларуская мова

Български

ქართული

Kurdî

Кыргызча