Application Fields of Hollow Glass Microspheres

Aug 18, 2023|

Aug 18, 2023| View:236

View:236Application Fields of Hollow Glass Microspheres

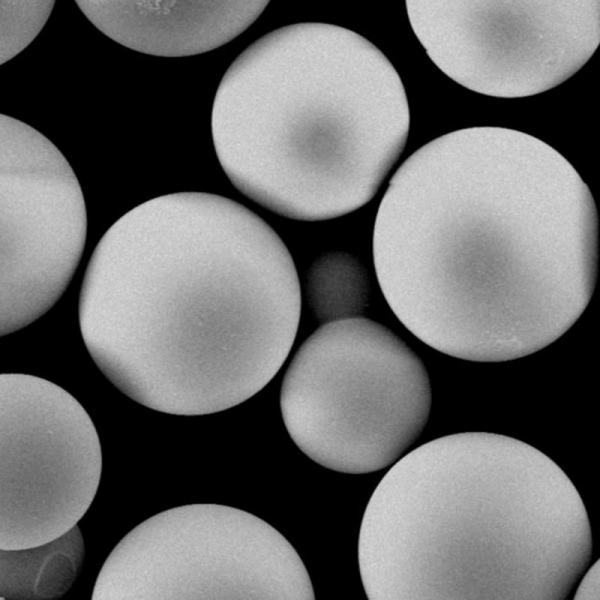

HollowGlassMicrospheresisakindof ultra-lightweightinorganicnon-metallicmaterialwithhollowstructure,and it isa versatileand high-performance new lightweightmaterialdevelopedinrecent years.

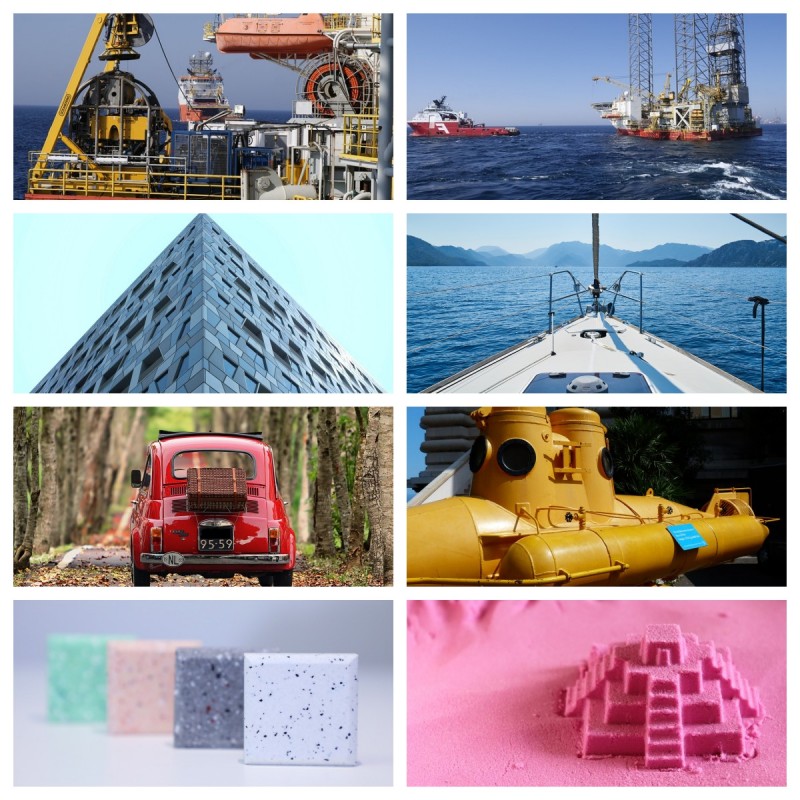

1. Oil and gas field field field

In oil extraction, hollow glass microspheres can effectively reduce the density of drilling fluid and cementing cement slurry. During drilling, drilling fluid containing hollow glass microspheres not only has the characteristic of low density, but also the spherical physical structure of the microspheres has a high lubricity effect on the drill bit, reducing the wear of the drill bit

2. The field of thermal insulation coatings

Hollow glass microspheres not only have high solar reflectance, but also have extremely low thermal conductivity. Applying hollow glass microspheres as functional fillers to thermal insulation coatings can not only improve the insulation and insulation properties of the coating, but also improve the hardness, covering, scratch resistance, aging resistance, and flame retardancy of the coating film. It can also reduce the amount of film forming agent, increase the volume concentration of PVC pigments in the coating, and reduce the VOC volatile organic compound content in the coating factory.

It can also be added to putty to reduce putty polishing time and dust.

3. Rubber and plastic industry

It can be filled into most thermosetting and thermoplastic resins, such as epoxy resin, phenolic resin, acrylic resin, unsaturated polyester, nylon, rubber, etc. It can not only increase resin fluidity, reduce product density, but also improve the impact strength, tensile strength, and wear resistance of the product. At present, hollow glass microspheres have been widely used in fields such as fiberglass, handicrafts, household appliances, insulation equipment, ships, automobiles, deep-sea floating bodies, and aerospace.

4. The field of artificial marble and artificial wood.

Improve the mechanical processing, impact resistance, cracking resistance, coloring, natural texture, and color continuity of products. It can also effectively reduce the weight of products and reduce transportation and installation costs.

View More(Total0)Comment lists